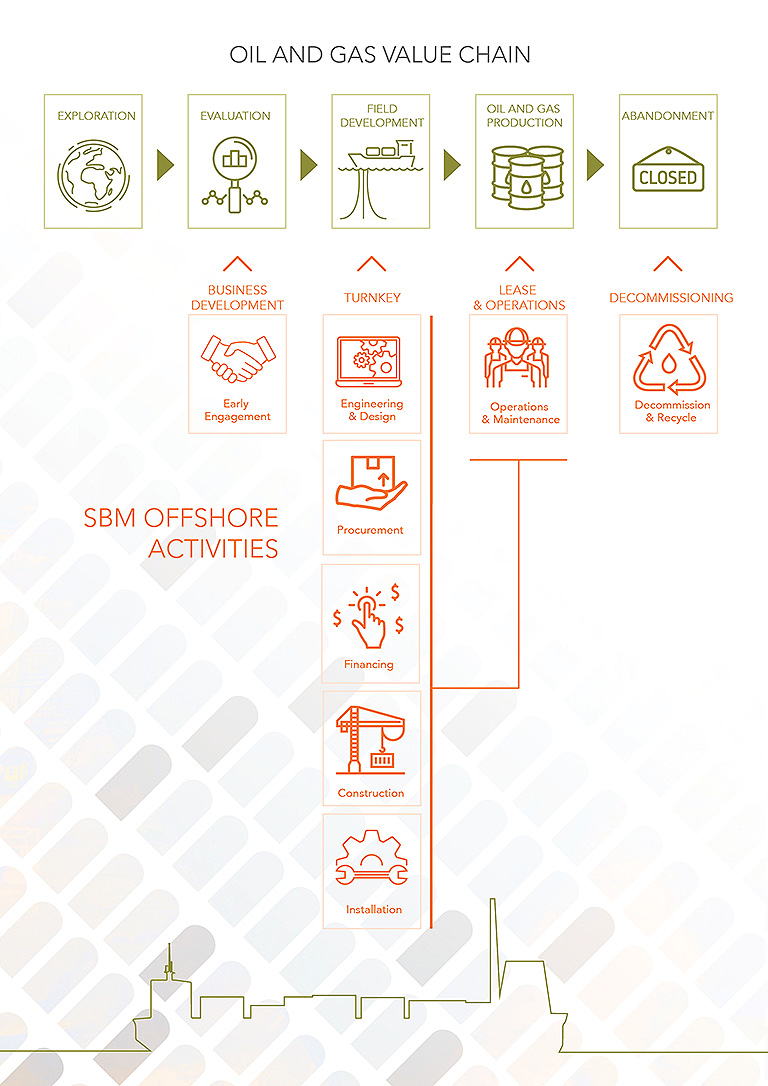

1.6Position within the Value Chain

In line with its vision, SBM Offshore provides a broad range of products and services to its clients, aiming to unlock the potential energy that the oceans contain. The next illustration outlines the lifecycle phases of the oil and gas industry at large and SBM Offshore’s activities within this cycle. The Company is also preparing for the energy transition by focusing on the renewable energy market, as illustrated at the end of this section.

The Company’s clients usually control the complete value chain, from the initial offshore exploration phase to the physical distribution of hydrocarbon-based fuels. SBM Offshore’s added value in this value chain primarily relates to field development activities. The Company is to a lesser extent involved in the transportation of hydrocarbons via its CALM Buoys to transfer crude oil.

SBM Offshore’s OIL AND GAS Value Chain

SBM Offshore’s value chain is reflected in the full lifecycle of producing offshore energy for its clients. The Company aims to add value to each lifecycle phase, leveraging its experience to succeed in winning business, executing projects on time and on budget and operating its fleet at maximum efficiency.

Engineering and Design

SBM Offshore has the capability for conceptual studies, basic design and detailed design through in-house or in-sourced resources. SBM Offshore invests in product and technology development to maintain the required technology innovation and expertise to meet its clients’ requirements for specific field development and to increase its competitive advantage.

Procurement

SBM Offshore’s supply chain represents a substantial part of the total costs of constructing a Floating Production System. In line with its Fast4WardTM philosophy, the Company fosters an integrated supply chain, partnering with suppliers to develop efficient delivery of bulk, equipment and services.

Financing

The Company ensures optimum results for clients by offering various financial models:

- In the case of a Lease and Operate contract, the facility is sold to asset specific companies − SBM Offshore usually retains a majority stake − to charter and operate the asset for the client throughout its lifecycle.

- In the case of a direct sale, the construction is financed by the client, and a margin is generated from the Turnkey sale.

- In the case of a hybrid of the two above, such as the build-operate-transfer model (BOT), SBM Offshore builds and commissions the unit, operating it during a defined period (the crucial start-up phase). The transfer of ownership to the client then occurs at the end of this defined period.

Construction

While maintaining responsibility for delivery and project management, SBM Offshore outsources most construction activities (for either conversion or new build Floating Production Systems) and has agreements in place with yards that allow delivery of Floating Production Systems through different execution models and local content requirements. SBM Offshore provides value through integration and project management.

Installation

Installation of the floating facilities is done with specialized installation vessels and requires specific engineering expertise and project management skills. SBM Offshore is the co-owner of two installation vessels that provide the expertise to install its fleet of Floating Production Systems offshore, as well as performing other offshore works for third parties. Access to these vessels allows SBM Offshore to control the risks associated with cost fluctuations over a period of several years from contract award.

Operations & Maintenance

The asset specific companies, fully owned by SBM Offshore or co-owned with partners, which lease offshore facilities to clients, mostly operate such facilities as well. This activity creates value for clients, as the uptime performance of the facility directly impacts the amount of hydrocarbons produced. In most contracts, these asset specific companies are compensated for providing the production facilities by a fixed dayrate complemented by an operating fee. Income is independent of oil price fluctuations.

Most contracts include a bonus/penalty reward related to uptime performance of the different systems, as well as penalties related to greenhouse gases (GHG) emission levels. The FPSO facility processes the well fluids into stabilized crude oil for temporary storage on board, which is then transferred to a shuttle tanker to export it from the field. Oil and gas enhanced recovery systems are used to maintain production levels. To do this, secondary recovery systems for gas injection, water injection and gas lift systems are installed on the production facility. SBM Offshore’s latest FPSO designs can include CO2 removal from gas streams and reinjection into the well offshore. Operating and maintaining floating production facilities requires proven operational expertise and a robust management system, which SBM Offshore has developed almost 320 cumulative contract years of operations.

Decommissioning & Recycling

At the end of the lifecycle the facilities are decommissioned and recycled. As the leased FPSOs are under SBM Offshore’s full or co-ownership, the Company applies the Hong Kong Convention rules to green recycle its FPSOs.

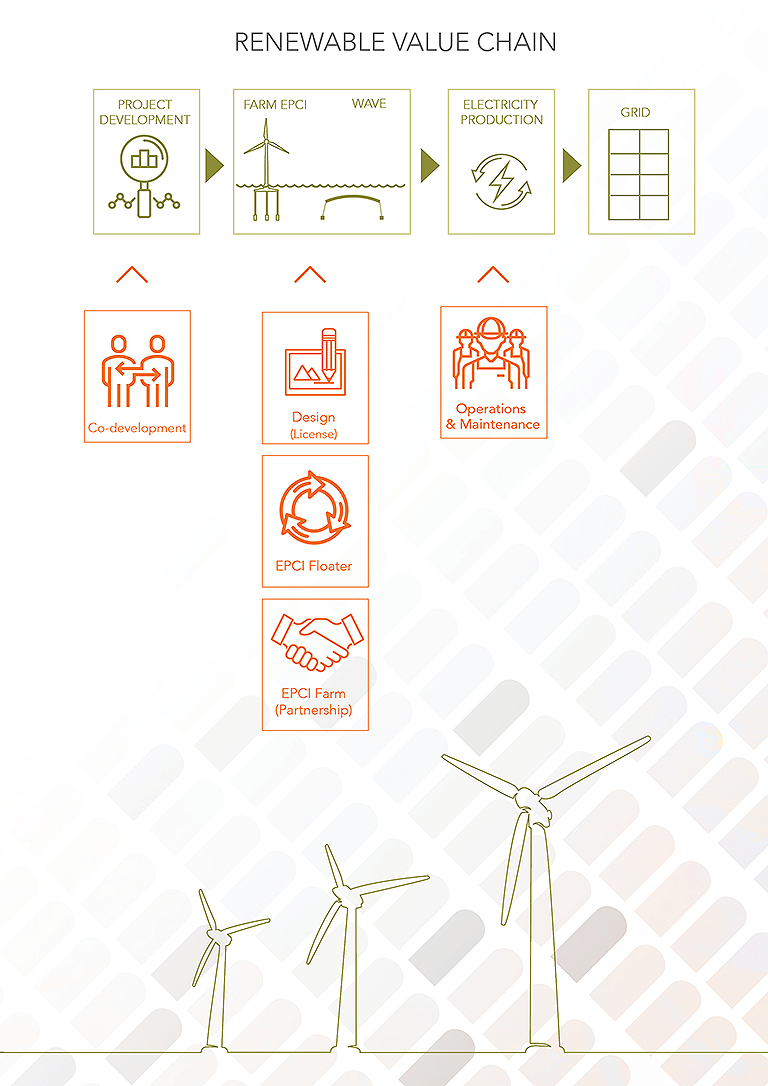

renewable energy Value Chain

Energy Transition

SBM Offshore’s strategy is to position the Company in this growing market sector as the energy mix evolves, with a more dominant role for renewables. SBM Offshore is investing in technology development for renewable energy, especially in floating offshore wind and wave energy. The Company’s Renewables Product Line is focusing on developing its expertise, as well as identifying opportunities for technology co-development with clients and partners.